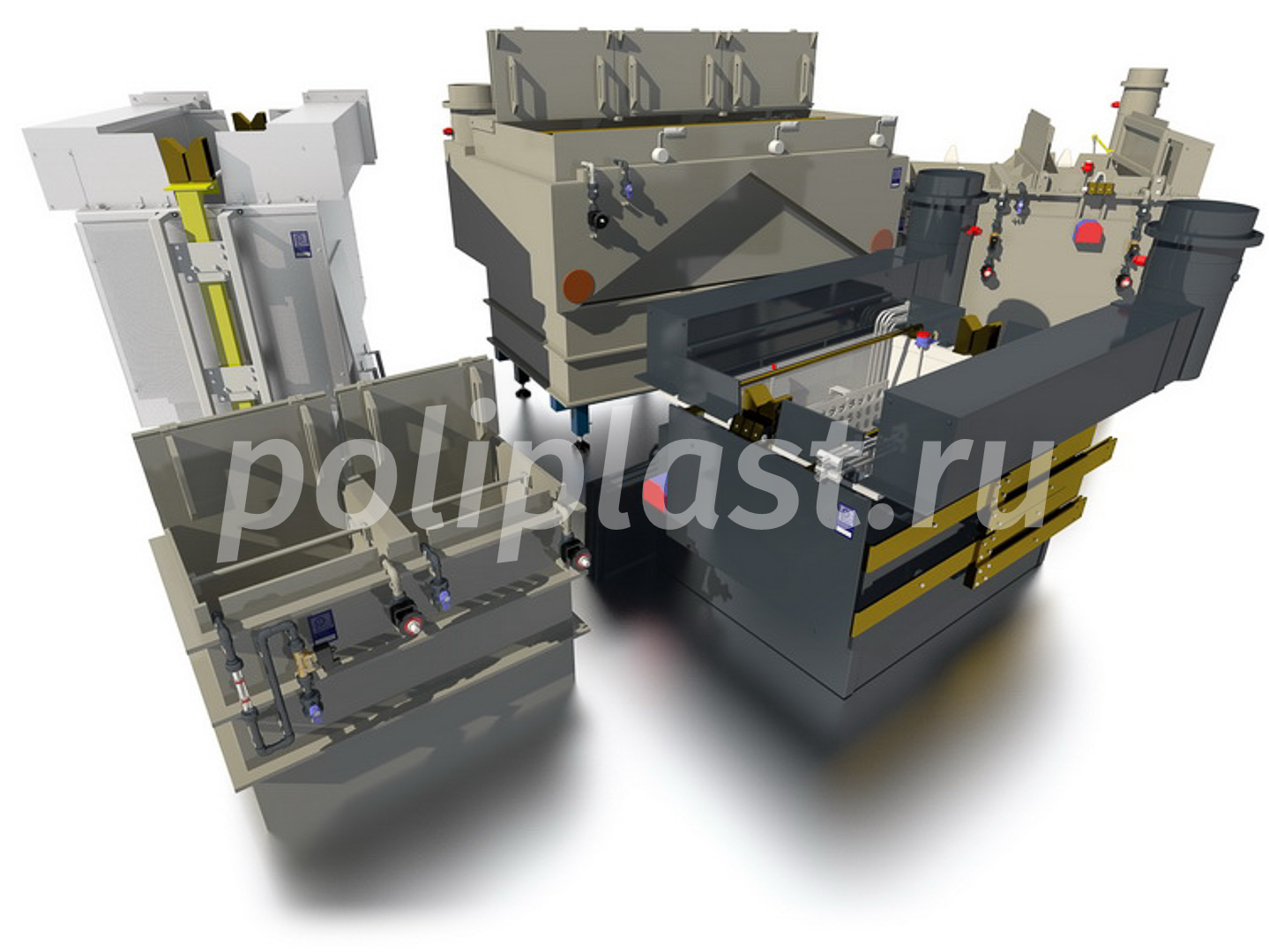

Electroplating tanks

Since 1991, Poliplast has been specializing in the designing and manufacture of electroplating equipment, including tanks for chemical and electrochemical treatment and coatings.

The company has a number of patents for inventions, uses its own technologies for painting of metal structures and protection of welds from corrosion.

For manufacture of the electroplating tanks, chemically resistant plastics are used: polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinylidene fluoride (PVDF). Also, metals are used (titanium alloys, stainless steel) to ensure a long lifespan of products. Poliplast LLC manufactures tanks for a wide range of processes.

The company has a number of patents for inventions, uses its own technologies for painting of metal structures and protection of welds from corrosion.

For manufacture of the electroplating tanks, chemically resistant plastics are used: polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinylidene fluoride (PVDF). Also, metals are used (titanium alloys, stainless steel) to ensure a long lifespan of products. Poliplast LLC manufactures tanks for a wide range of processes.

Surface preparation tanks:

Parts degreasing tanksThe majority of the coating processes begin with a degreasing operation. Depending on the nature of contamination and the material of parts, the following tanks are used:

|

The equipment of the degreasing tanks may be supplemented with the following units:

Also, if necessary, they are equipped with the above devices, with the exception of current-carrying rods.

At Poliplast, it is possible to buy non-standard electroplating tanks at the request of the Customer.

The internal dimensions depend on:

The current purchase prices of the electroplating tanks may be obtained by phone +7 (8112) 29-20-50, by e-mail marketing@galvanica.ru or by filling in the feedback form.

- heating unit,

- unit for cleaning of the solution surface,

- filtration unit,

- automatic level maintenance unit.

Tanks for scale loosening, etching, removal of smut, activationThey are designed to remove scale, corrosion products, smut, and oxide films from the surfaces of parts immediately before applying the coating. |

Chemical and electrochemical polishing tanks.They are used to reduce the surface roughness of parts and for gloss. |

Metal and alloy coating tanks:

Zinc plating, cadmium plating, copper plating, chrome plating tanks, etc.They are used to obtain protective, protective & decorative, as well as special coatings that allow solving such tasks as protection of metals from corrosion, obtaining of increased hardness and wear resistance of the surface of parts, improved antifriction properties, facilitation of solderability and improvement of the appearance of products. |

Precious metals coating tanks.The tanks for gilding, silvering, application of palladium and other precious metals are used both in the jewelry business and in the radio-electronic, instrument-making and aviation industries. |

Non-metallic inorganic coating tanks:

Phosphating tanksThey are designed for application of a high-strength film onto the surface of parts, which prevents the occurrence of corrosion spots. Owing to a significant improvement in the adhesive properties, the phosphating operations is also used as a preparation before painting. |

Chemical oxidation tanksThey are designed to produce protective and decorative coatings on the surface of copper alloys, nickel, silver, various steels and cast iron. |

Anodic oxidation (anodizing) tanksThey are used to produce oxide coatings on the surface of various metals and alloys (aluminum, copper, titanium, etc.) by an electrochemical method. |

Tanks for additional treatment of coatings:

Bright-dip tanksThe bright dip, for example, of zinc or cadmium coatings, is made in order to increase their corrosion resistance and make a decorative appearance of the surface of parts. |

Passivating tanksThe process of passivation of metals consists in the formation of thin films of an oxide or oxide-salt nature on their surface. The passivation of coatings increases much their resistance to corrosion. |

Chromating tanksThey are designed for passivation of parts in solutions based on chromic acid or its salts. |

Tanks for chemical and electrochemical removal of defective coatingsThey make it possible to eliminate the consequences of errors, made during the performance of previous operations, and to obtain a coating on the same workpiece, which would meet the specified requirements. |

Types of electroplating tanks

The types and design specific features of the tanks differ depending on their intended use.

Rinsing tanksThey are used to remove contaminants, residues of solutions and electrolytes from parts. Poliplast produces both single-stage and multi-stage (direct-flow and counter-flow) tanks. The use of countercurrent (multi-stage) rinsing tanks reduces much the water consumption while maintaining the rinsing quality.The tanks are assembled from standardized units: a body, an overflow pocket, a bubbler, a filling pipe, drain pipes with shut-off valves. In addition, there may be systems for spraying jet rinsing when lifting products. The warm and hot rinsing tanks are equipped with lids, heaters, temperature and level sensors; their bodies are thermally insulated. More → |

Electrochemical coating and treatment tanksThey are used in the processes of electrochemical degreasing, polishing, coating removal, in the application of various coatings: chrome plating, zinc plating, cadmium plating, copper plating, nickel plating, etc.The tanks may be equipped with heating elements and heat exchangers for heating and cooling, a heating/cooling control system with level and temperature sensors, thermal insulation, rod position control systems, side exhaust pipes, lids, water supply pipes, drain pipes with shut-off valves, etc. It is possible to connect chillers, filtration units, chemically resistant pumps, ejector stirring systems and other equipment. More → |

Chemical coating and treatment tanksThey are intended for preparatory process operations, coating operations and additional chemical treatment operations.More → |

Bulk parts treatment tanks

Bell tanksThey are used for electroplating of small parts in bulk. The volume of the tank bells, produced by Poliplast LLC, varies from 15 dm3 to 63 dm3, the load of parts is 5 to 25 kg.They may be equipped with heat exchangers (coils), electric heaters and anode rods with holders. The bell rotation is controlled from the control panel. More → |

Barrel tanksThey are designed for application of electroplating coatings onto small parts in bulk.Their structure consists of an electrolyte tank, made of carbon steel lined with polypropylene sheets and having a chemically resistant painting, a movable carriage with an electroplating barrel, a polypropylene lid that simultaneously serves as a tray for unloading of parts, a device for control of the lifting and rotation of the barrel. The barrel tank is produced with a polypropylene reservoir. More → |

The internal dimensions depend on:

- the size of parts to be coated;

- capacity of the electroplating line;

- installation of internal modules;

- number of electrode rows and distance between them

The current purchase prices of the electroplating tanks may be obtained by phone +7 (8112) 29-20-50, by e-mail marketing@galvanica.ru or by filling in the feedback form.